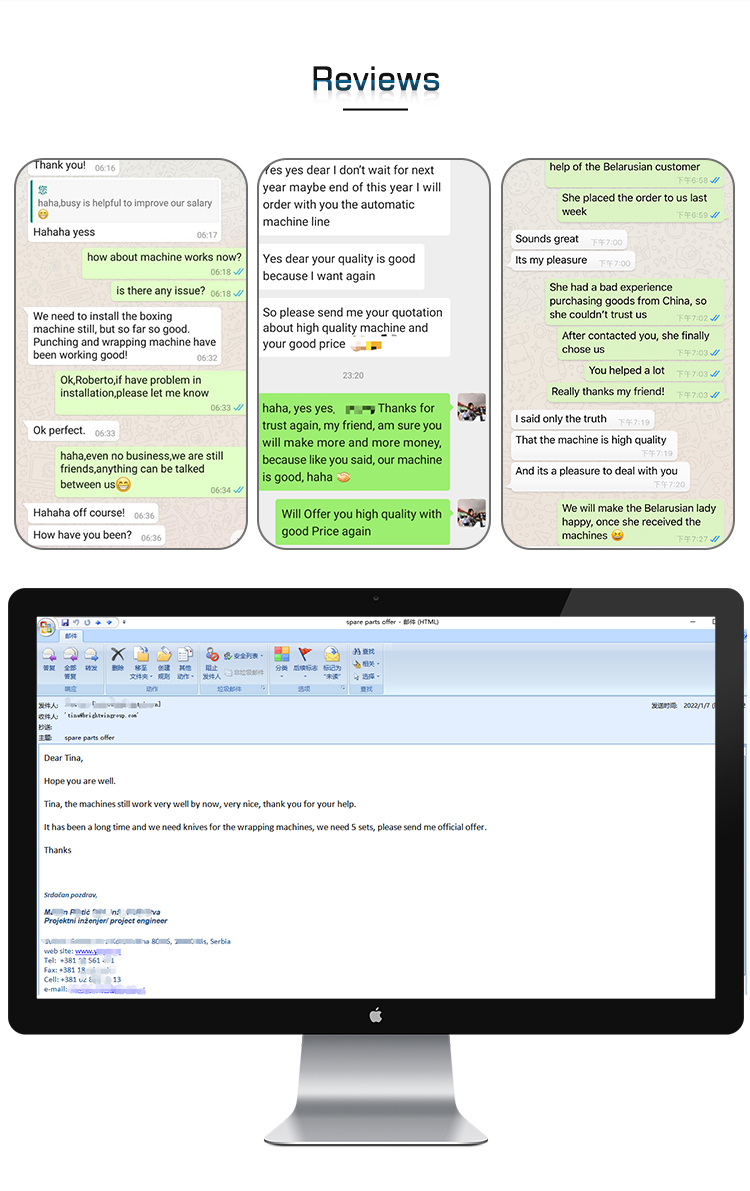

Side seal Wrapping machine

Overview of Brightwin cubes side sealing wrapping machine

This wrapping machine is used to wrap pack solid square and rectangle products into film(paper, aluminium, glutinous rice paper, etc.) such as bouillon cube, chicken cube, nougat, seasoning cube, soup cube, beef cube, shrimp cube, chocolate, and candy etc.

According to different requirement there has single paper packing or double-deck paper packing.

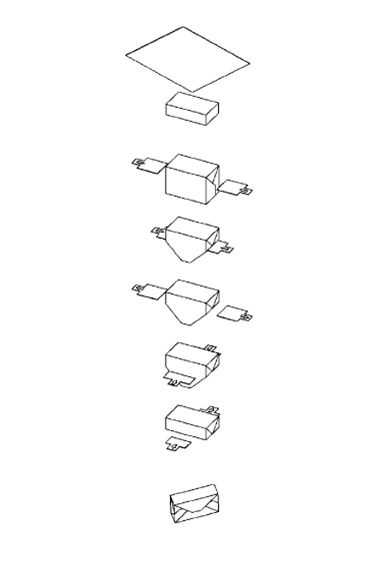

Wrapped samples of Brightwin cubes side sealing wrapping machine

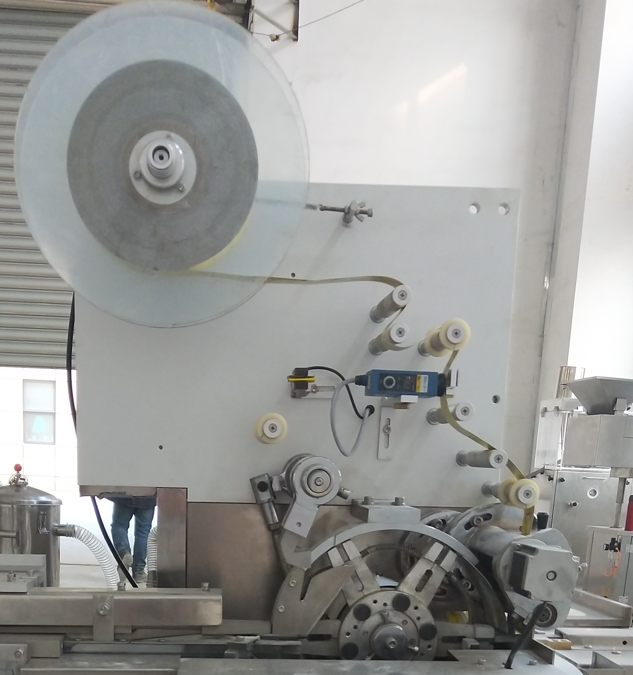

Principle of Brightwin cubes side sealing wrapping machine

The machine wraps the cubes fully automatically by charging the products into a inlet conveyor, and the cubes transported along the conveyor close to the machine. The cube is pushed forward by a push rod when it comes right in front of a wrapping former. At this time wrapping material prepared before a cube is fed by a paper feeder via paper feeding channel, and is cut to a predetermined size. A piece of wrapping material wrapps a cube is holding in the former, and four cornered pack except right side fold is made. Then the product will be clamped in the rotating former sidk, when the disk rotates, the folder devices installed on both sides simultaneously swing to fold the paper at both ends of the cube into shape. Finally the cube is rotated to the 180° horizontal postion, two clamps clamp it and bring it into the heating and sealing track at the same time the last part of the film and foled coner will be folded and heated stick to the cube sides, the product is completely wrapped and is discharged one by one.

The working steps of Brightwin cubes side sealing wrapping machine

Step 1: film feeding and cutting

Step 2: cubes feeding

Step 3: cubes are wrapped by film

The packing theory of the cubes side sealing wrapping machine

Step 4: Wrapped cubes are transported out

New design of the Brightwin cubes side sealing wrapping machine: wrapping with Easy tear strip

After added the easy tear strip the wrapped cubes will be easily to tear up by pull the easy tear stip.

Defferent appearance of the cubes side sealing machine with easy tear stip:

Overview of Brightwin cubes side sealing wrapping machine

1. It adopts Globoidal indexing cam mechanism, with high indexing accuracy, stable operate and low noises.

2.Use Globoidal indexing cam mechanical system, high degree of precision, stable running and no noise.

3. The speed can be adjusted through transducer.

4. The machine has automatic alignment device for the pattern on packing paper.

5. PLC & microcomputer control

6. Photo-electrical positioning, stepper motor control paper feeding

7. AC inverter speed control

8. Automatic folding and sealing

9. Easy operation, high efficiency, labor saving, easy maintenance

10. Meet GMP requirement

Parameters of Brightwin cubes side sealing wrapping machine

| Model | BW-W |

| Speed | 180-250pieces/min |

| Shape | rectangle |

| Product size | max length:40mm, max width: 30mm, max height: 20mm |

| Packing material | wax paper, Aluminum thin, art paper, wafer, glutinous rice paper |

| owder | 1.5KW |

| Machine dimension | 2000mm×1350mm×1600mm |

| Weight | 800KG |

If you have other capacity need, please contact us for customize machine.