OEM/ODM Supplier Body Lotion Filling Machine - Rotary doypack pouch granule packing machine – Brightwin

OEM/ODM Supplier Body Lotion Filling Machine - Rotary doypack pouch granule packing machine – Brightwin Detail:

Application Area

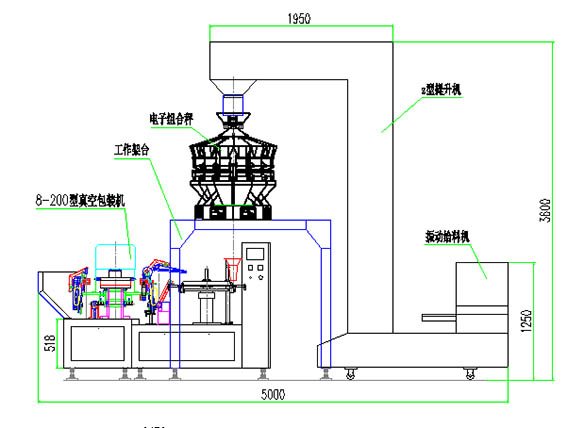

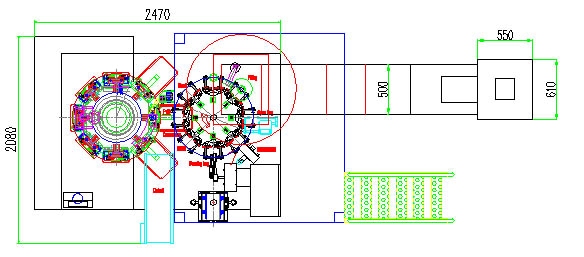

This rotary packing line mainly installs rotary packing machine, electronic scale and conveyor etc, suitable for packing all kinds of granule, such as nuts, preserved fruit, additives etc.

Main technical parameters

| Model | BW-P |

| Packing Speed | 15-50bags/min (Depended on the product and filling weight) |

| Bag Size | W:130-250mm L:150-300mm |

| Filling Range | 5-1500g |

| Total Power | 4.75kw |

| Bag Types | All kinds of compound bags, such as flat bag, 3-side sealing bag,4-side sealing bag, zipper bag, standup bag etc… |

| Overall Dimensions | 4200*1800*2400mm |

Main Configuration

| No | Parts Name | Model | Quantity | Manufacturer |

| 1 | PLC | CP1-M40DT-D | 1 | OMRON(Japan) |

| 2 | Panel | TK6070i | 1 | Weinview(Taiwan) |

| 3 | Transducer | ATV312HV075N4 | 1 | SCHNEIDER(France) |

| 4 | Vacuum Pump | KRX5-P-V-03 | 1 | ORION(Japan) |

| 5 | Ribbon Coder | 1 | China | |

| 6 | Main Motor | 1 | China | |

| 7 | Stainless Steel Heater | 2 | China | |

| 8 | Proximity Switch | 2 | OMRON(Japan) | |

| 9 | Solenoid Valve | SY5120-5DD-01 | 10 | SMC(Japan) |

| VQ21A1-5G-C8-F | 2 | |||

| VP342R-5G-02A | 2 | |||

| 10 | Cylinder | CJ2D16-20 | 2 | SMC(Japan) |

| CG1BN20-20 | 1 | |||

| CG1BN32-40 | 1 | |||

| CQ2A20-20DM | 1 | |||

| CQ2A25-20DM | 1 | |||

| CQ2A40-35DM | 1 |

Electronic scale

This machine will use SUS316 for product contact parts. Program recovery function can reduce operation failure. Adopts Tread Patterns type weigher, and the vibration hopper is 75 angle incline. PLC control, easy to operate, no bottle, no filling. All the hoppers can be opened make cleaning easy and quick; The weigh hopper can be preset to open in order (staggered) to avoid blockages with puffy or problem products. Multilanguage control panel, Spanish, Korea, German, French and Arabic, etc. The function of measurement by counting pieces or components to satisfy your various requirements.

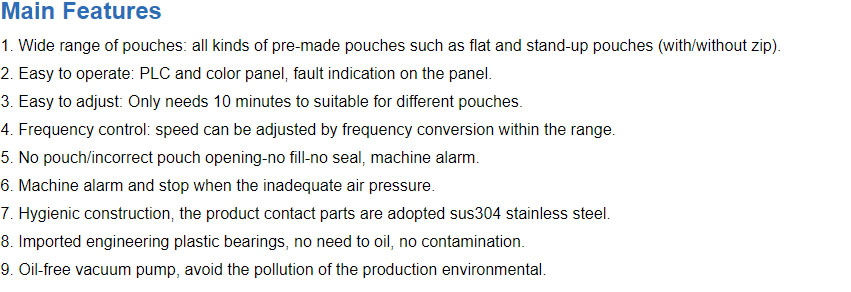

Feature

1. Choose the best weight combination from the multi-combination by computer, its fast and accurate.

2. Can instore 99 groups of parameters beforehand.

3. The weight in each bottle can be set in touch screen.

4. Can use different model of electronic scale according to different weight and capacity.

5. The whole line is adjustable, it is suitable for different bottle sizes and shapes by adjusting or change some parts.

6. It is designed and manufactured according to customers’ different products, containers and requirements like capacity etc.

7. The electrical elements brands can be customized.

8. The voltage is customized

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for OEM/ODM Supplier Body Lotion Filling Machine - Rotary doypack pouch granule packing machine – Brightwin , The product will supply to all over the world, such as: Bangkok, Algeria, Guyana, Our objective is "to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us". If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.