OEM Customized Filling Oil Machine - Granule weighing and filling machine – Brightwin

OEM Customized Filling Oil Machine - Granule weighing and filling machine – Brightwin Detail:

Overview

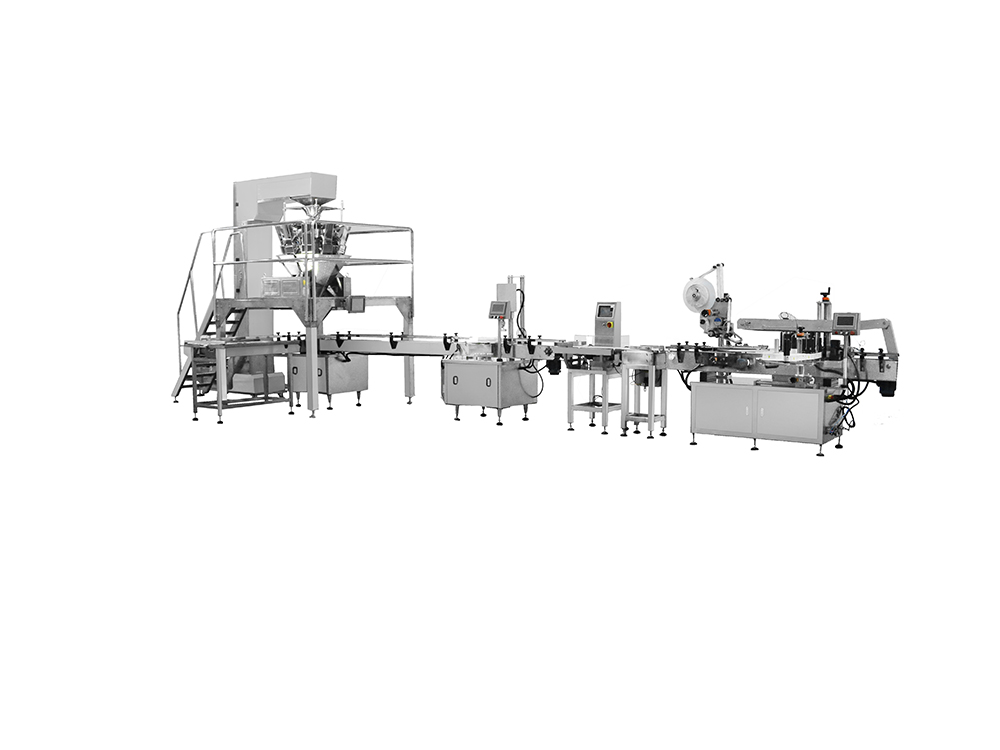

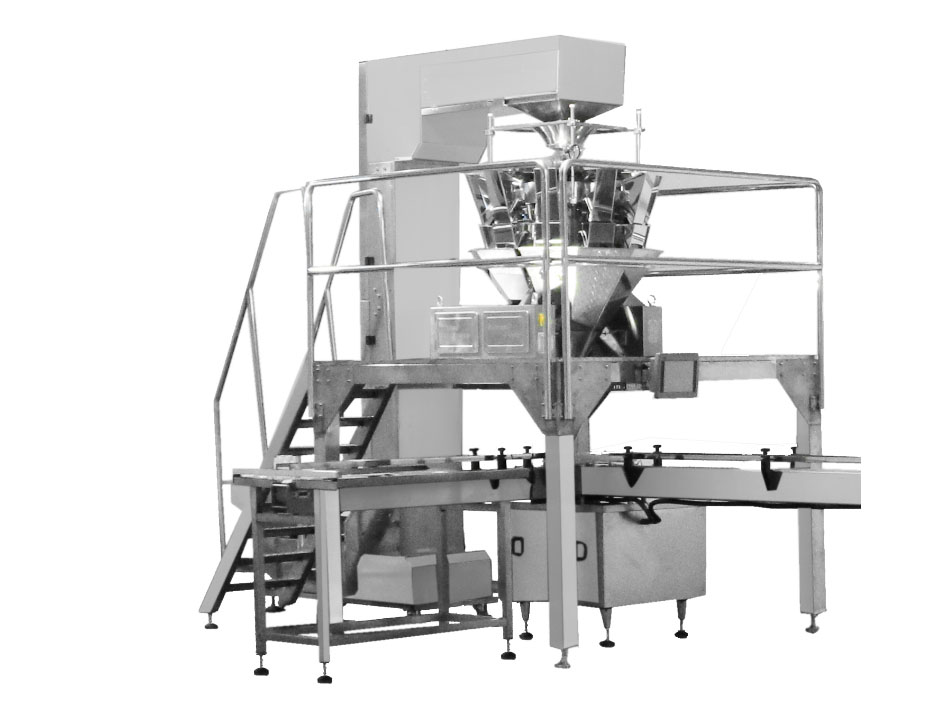

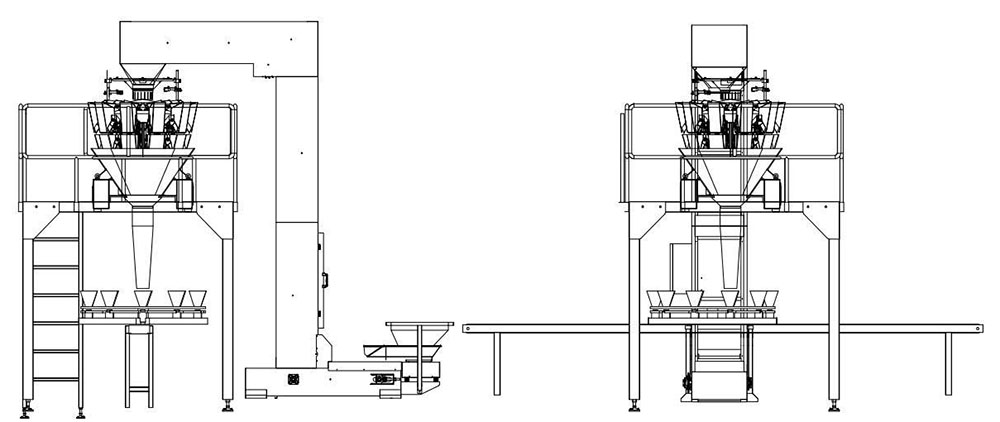

This machine will use SUS316 for product contact parts. Program recovery function can reduce operation failure. Adopts Tread Patterns type weigher, and the vibration hopper is 75 angle incline. PLC control, easy to operate, no bottle, no filling. All the hoppers can be opened make cleaning easy and quick; The weigh hopper can be preset to open in order (staggered) to avoid blockages with puffy or problem products. Multilanguage control panel, Spanish, Korea, German, French and Arabic, etc. The function of measurement by counting pieces or components to satisfy your various requirements.

This platform is beautiful, strong, has prevent slippery mesa, practical and safety. Mainly made of 304 stainless steel which is clean and health.

Most of all, the machine equipped with electronic combination weighing machine. It is important equipment for the automatic quantitative packaging system.

(Granule filling line can finish weighing, filling, capping, sealing, weight detecting and labeling etc. It is applicable for various containers like plastic bottles, glass bottles and cans etc.)

Feature

1.The weight in each bottle can be set in touch screen.

2.Can use different model of electronic scale according to different weight and capacity.

3.The whole line is adjustable, it is suitable for different bottle sizes and shapes by adjusting or change some parts.

4.It is designed and manufactured according to customers’ different products, containers and requirements like capacity etc.

5.The electrical elements brands can be customized.

6.The voltage is customized

Parameter

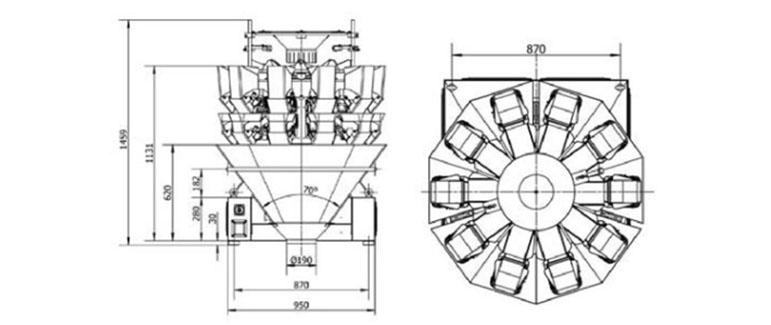

Weigh range:10-500g*n

Precision:0.5-2g

Max speed: 40-50 times/min

Power: 220V, 50HZ

Hopper volume:1.3L

Diamension:1436*1086*1258mm

Product detail pictures:

Related Product Guide:

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for OEM Customized Filling Oil Machine - Granule weighing and filling machine – Brightwin , The product will supply to all over the world, such as: Mauritania, Bulgaria, New Zealand, We follow up the career and aspiration of our elder generation, and we are eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.