semi-automatic cube carton tray packing machine

The machine is our new design, it’s suitable for boxing cubes, medicine, cosmetics, and goods etc. It is a semi-automatic multi-layer boxing machine. After the products are arranged, the cylinder will push them into the mold to complete the arrangement.

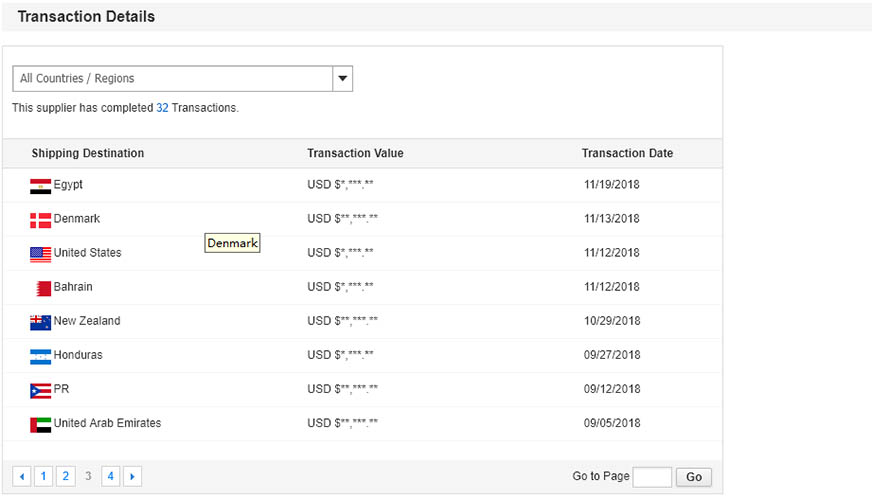

Specifications

●Thickness 2 mm SUS304 plate, and square tube,

●Mitsubishi PLC control,

●International brands Electrical components (as the Main Components list),

●High speed (120 cubes per minute),

●Easy to install, operate, clean, and repair,

●Just need to change few parts for different size carton.

Parameter

Capacity: 5-10 boxes per minute

Dimensions of the machine: 1800*300*950mm

Layer number: 3

Box size:

24pcs: 127mm*103mm*44.3mm (L*W*H)

12pcs: 103mm*65mm*44.3mm (L*W*H)

The cube dimensions: 50.7mm*30.7mm*13.8mm (L*W*H).

Voltage: 220V 50Hz (customized)

Air consumption: 0.2m³/minute

Power: 500W

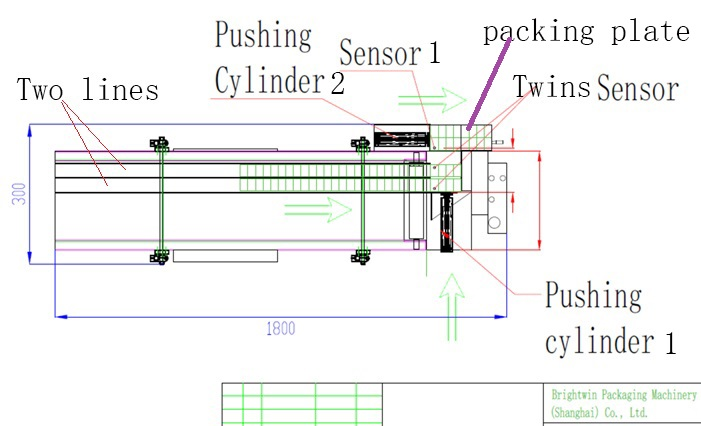

As the following drawing, the cubes come in two lines at the same time. Sensors will be installed at fixed places

Working steps:

1.When the twins sensor detect cubes at the same time, pushing cylinder 1 pushes 8 cubes to the next position.

2.After pushing cylinder 1 finishes twice pushing, sensor 1 will detect cube at it’s position, then pushing cylinder 2 will push 12 cubes to the third position.

3.The Packing plate get down one layer height to wait the second layer and the third layer.

4.When 3 layers collect at plate as the fixed arrangement, packing plate will up back to the origin height.

5.Worker covers a carton over the plate, and rotate the plate by handle, cubes will be packed onto the carton very well.

After sales services:

1.Offer professional operation manual

2.Online support

3.Video technical support

4.Free spare parts during warranty period

5.Field installation, commissioning and training

6.Field maintenance and repair service